Product Details

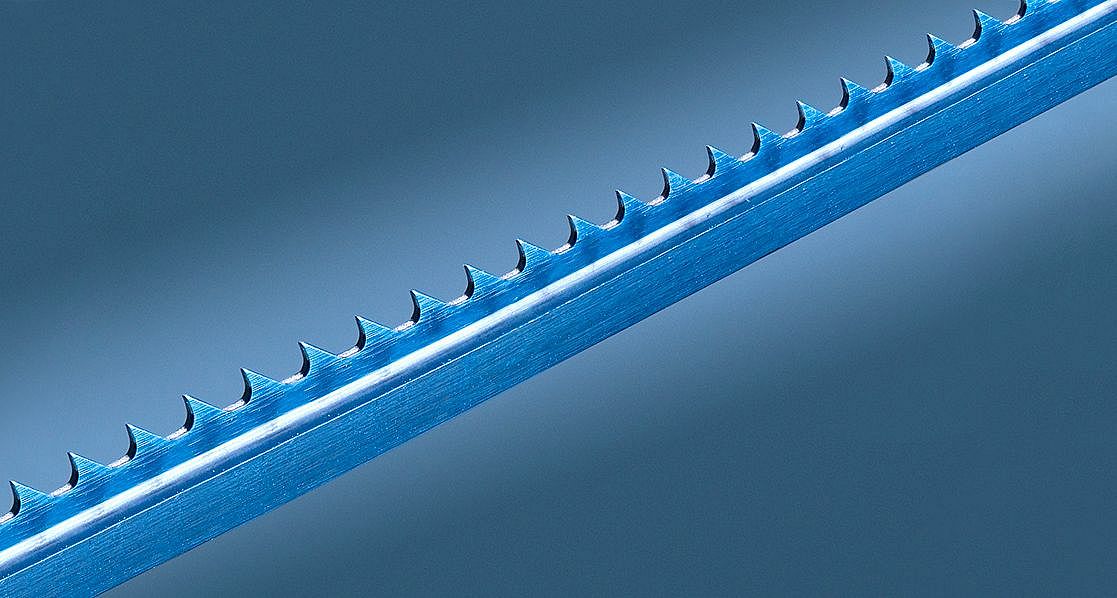

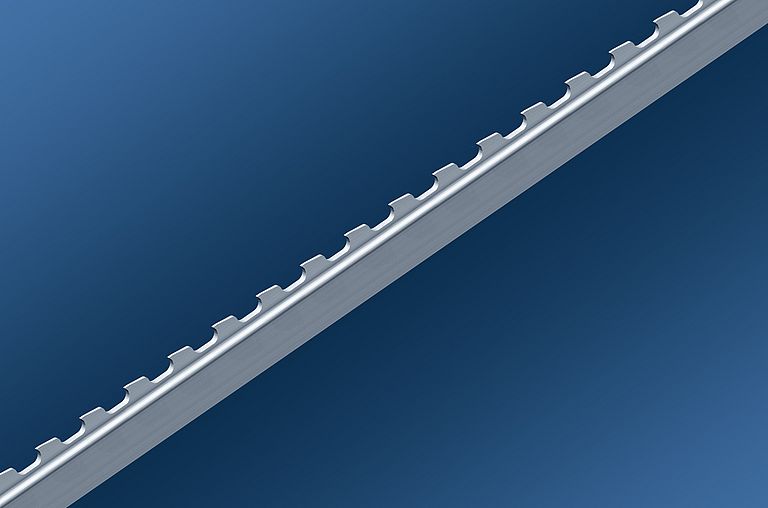

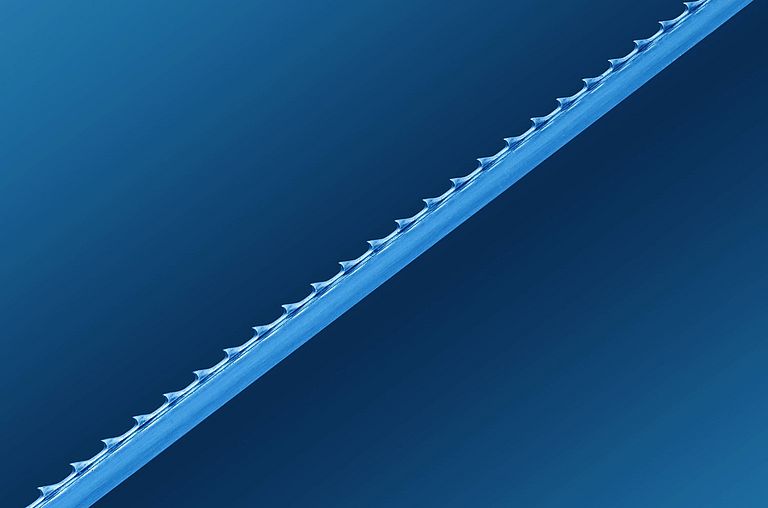

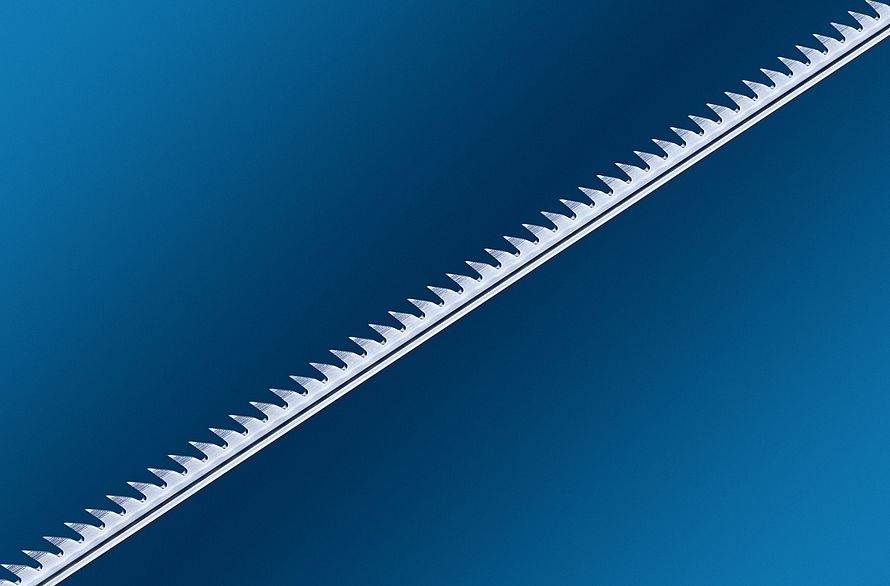

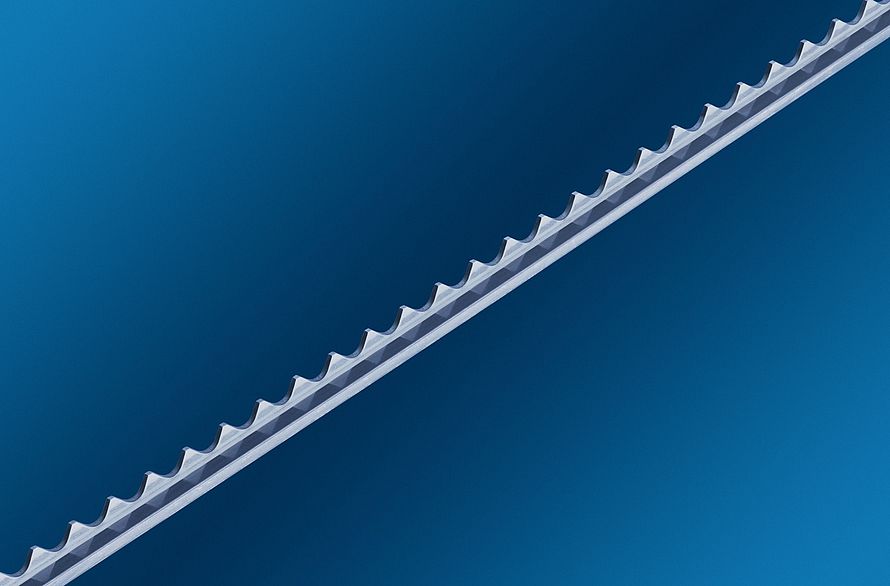

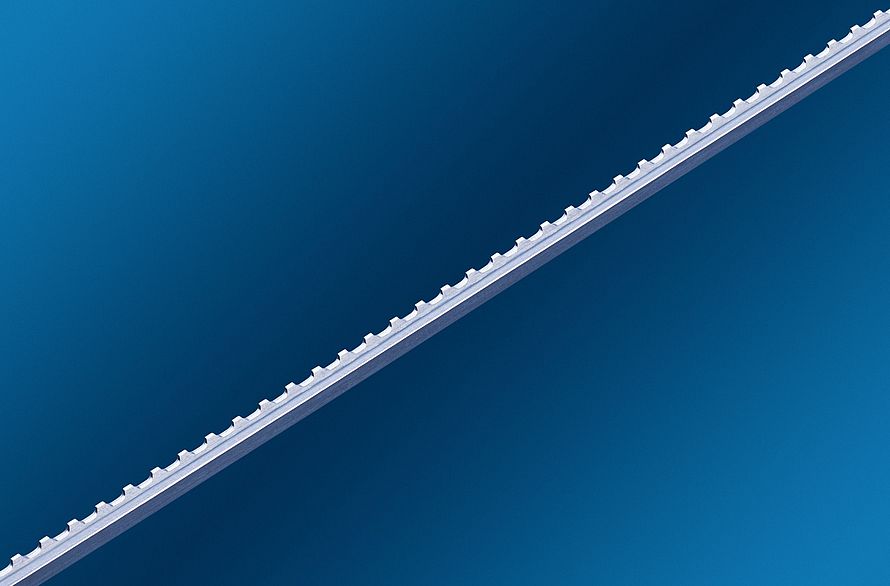

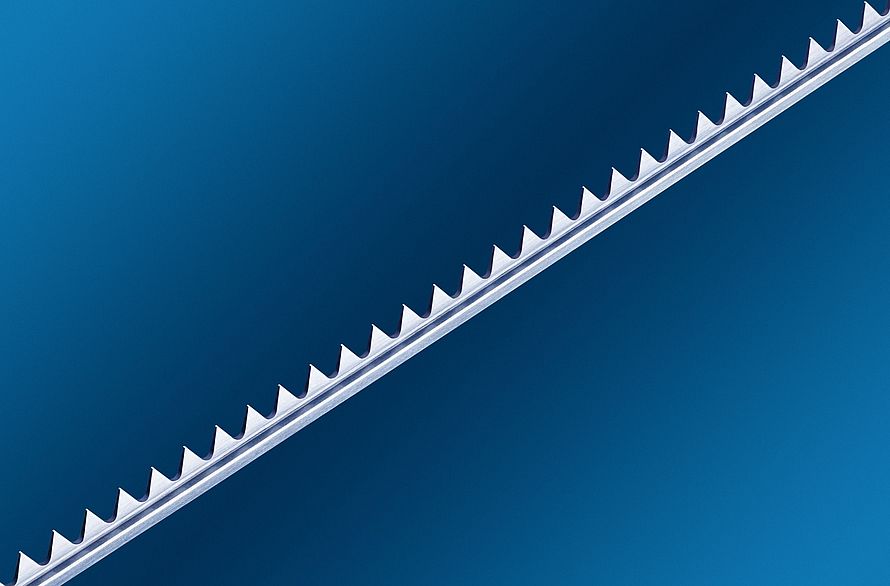

Carding wires from Graf are particularly gentle to fibers. Designed for consistent sliver quality and high process stability, they also offer an exceptionally long lifetime. Graf carding wires are suitable for cotton, man-made and regenerated fibers and will work across a wide range of carding applications, with numerous manufacturer systems and technologies.

The Graf portfolio covers carding wires for the widest possible range of card models and their demanding applications.