Product Details

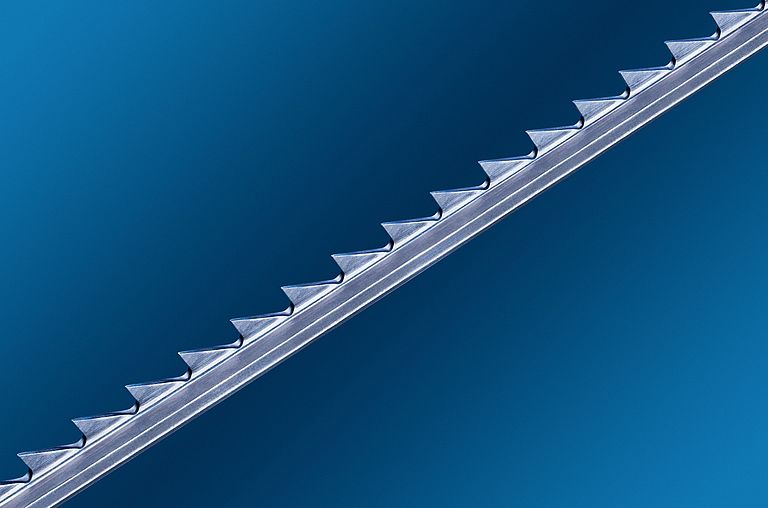

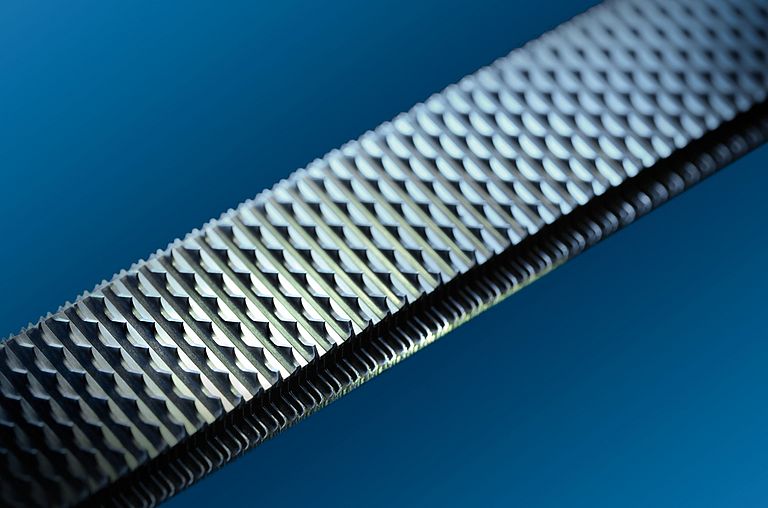

Operator-friendly adjustable settings and intensive mixing of the fibers increases the raw material utilization. Designed for durability and resilience, they also offer an exceptionally long lifetime. Graf clothing is suitable for cotton, man-made and regenerated fibers and will work across a wide range of blowroom applications.